For most homeowners, the garage door is something that’s just there and hopefully works when you push the button. But there’s actually a lot of interesting mechanics and engineering that goes into making garage doors open and close every day. Knowing a bit about how garage doors work, choose the right door for your home, and make sure it’s operating safely.

The Basics of Garage Door Operation

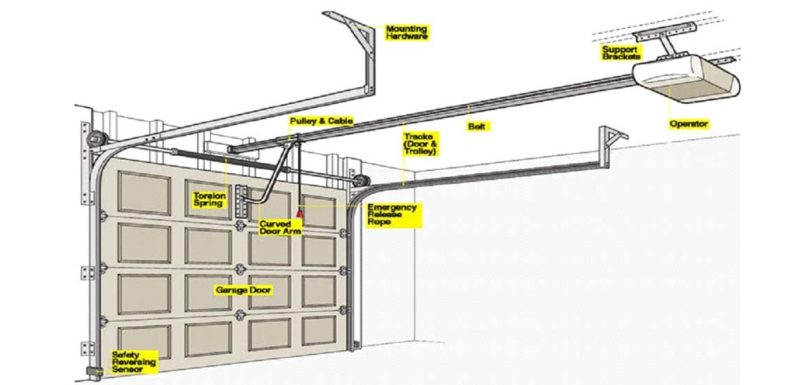

At its most basic, a garage door is a large barrier that moves up and down along vertical tracks to open and close off access to the garage. The door itself is often made of aluminum, steel, fiberglass, or wood sections that are hinged together to flex as the door moves. The tracks guide the door sections as they move and counterbalance springs provide assistance to lift the heavy door.

An electric garage door opener automates the opening and closing process. The opener consists of a power unit with an electric motor connected to a trolley that runs back and forth on the overhead track. The trolley connects to the top panel of the door and pulls the door open when powered on. A sensor detects the position of the door and signals the opener when to stop opening or closing.

The Tracks

Modern overhead garage doors use vertical tracks at both sides of the garage opening. The tracks are usually made of galvanized steel for durability. Along the backside of each track is a vertical piece called a flag bracket. The flag brackets mount rollers attached to either side of the top panel of the door. The rollers ride along the tracks, keeping the door panel aligned as it moves.

The vertical tracks are connected by curved or horizontal sections at the top corners. These horizontal track sections guide the rollers from the vertical tracks onto the horizontal track as the door opens. This allows the door sections to stack up neatly against the ceiling rather than intruding into the garage space. The arrangement where the door sections lift vertically and then follow a horizontal arc is called a vertical lift track.

Some garage doors use a compact track that allows installation very close to the garage ceiling. This is known as a low-headroom track. It uses an angled track section to transition from vertical to horizontal in a tighter space. Low headroom tracks are good when ceiling height is limited.

The Springs

Garage doors are heavy – often over 100 pounds for a single car door. That’s a lot of weight to lift and lower manually every day. Thankfully, springs provide a counterbalance to allow easy opening by hand or electric opener.

The two main types of garage door springs are:

- Torsion springs – These are mounted along a metal rod running above the door. The springs are anchored to the walls and connected to the rod. As the rod turns, it winds up the springs. The tension provides torque to help lift the weight of the door. Most modern garage doors use torsion spring systems.

- Extension springs – With this type, the springs run along either side of the horizontal tracks. One end is connected to an anchor bracket in the wall while the other is attached to the bottom corner of the door. As the door lowers, the springs stretch out to create tension. When the door closes, the springs contract again. Extension springs require safety containment cables running through the center to contain them if they break.

The springs are carefully calibrated based on the size and weight of the door so they can provide the right amount of assistance with opening and closing. There are also drums built into the ends of the torsion rod that allow fine-tuning of spring tension.

The Electric Opener

While you can open a garage door manually, most homeowners opt for the convenience of an automatic opener. There are several components that work together to open and close the door with the push of a button.

- Electric motor – Powerful electric motors provide the lifting force needed to open even large and heavy doors. Motors can be AC or DC-powered and deliver between 1/2 horsepower to 1 1/2 horsepower. Higher horsepower is needed for heavier solid doors than for lightweight aluminum doors.

- Gear and sprocket drive – The electric motor spins a drive gear that meshes with a sprocket on the torsion rod for torsion spring doors. This allows the motor to turn the rod and wind up the springs. For doors with extension springs, a drive belt turns a pulley that helps lift the door via cables.

- Trolley – This mechanism connects the drive system to the track and door. A trolley rides along the track, attached on one side to the torsion rod or drive pulley and on the other to the top panel of the door. As the trolley moves, it pulls the door open or pushes it closed.

- Limit switches – These switches stop the motor and reverse direction when the door reaches the fully open or closed position. They ensure the door doesn’t overwork the system and break something.

- Control panel – Wall-mounted control panels have buttons or switches to open and close the door. Keypads, fingerprint scanners, or remotes provide ways to operate the door without having to enter the garage.

The Door Sections

The door itself consists of individual panels connected together with hinges. The sections interlock to form a continuous surface. Typical section height is 18″-24″.

Several materials are used for garage door sections:

- Steel – Steel doors are durable and economical. Thin steel sheets have insulation on the inside for energy efficiency and quiet operation.

- Aluminum – Aluminum provides a lightweight option that’s still sturdy and low maintenance. Sections often have a baked-on enamel finish.

- Wood – Wood doors offer a classic, natural look and feel. Sturdy stiles and rails frame wood panels made of cedar, hemlock, or other weather-resistant species.

- Fiberglass – For a unique look, fiberglass garage doors have the appearance of real wood but with no risk of warping or rotting. They require less maintenance than real wood.

- Vinyl – Vinyl garage doors are lightweight for easy lifting and low cost. Their thicker insulation helps minimize heating/cooling costs.

Within the framed panel sections, some doors have windows for added natural daylight. Windows may be acrylic panels, smoked glass, clear glass, or other glazing. Designer window options let you add style to a plain door.

Garage Door Safety Mechanisms

Since garage doors are large, heavy objects that move under high tension, safety is a key concern. Garage doors incorporate several important safety mechanisms:

- Safety bottom brackets – The bottom panel of the door has a sensor edge along the bottom. If the door encounters an object while closing, the sensor reverses the door so it opens again.

- Photo eyes – An infrared beam shines across the door opening, projecting to a sensor on the other side. If something breaks the beam, it signals the opener to reverse direction.

- Automatic reverse – Garage door openers have a force setting that detects resistance if the door hits something. Sensing this resistance causes the opener to automatically stop and reverse.

- Backup batteries – Battery backup systems for openers allow the door to be opened and closed during power outages for emergency exit/entry.

- Manual release – A manual disconnect handle allows the door to be disconnected from the opener so it can be opened or closed manually in an emergency.

- Cable containment – For extension spring systems, safety containment cables run through the center of the springs. This captures the springs if they happen to break under tension.

Common Repairs and Maintenance

To keep your garage door operating smoothly for years to come, it’s a good idea to inspect components and perform some routine maintenance periodically. Here are some of the most common repairs and maintenance tasks:

- Lubricate rollers and hinges – Use a garage door lubricant spray twice a year to keep rollers sliding easily in their tracks and hinge joints moving freely. This prevents excess strain.

- Inspect cables – Cables can fray or unwind over time. Check cables carefully for wear and replace immediately if any are compromised. Frayed cables can snap suddenly under high tension.

- Test safety sensors and reverse – Use a broom handle or cardboard to break the photo eye beam and make sure the door reverses direction. Also, test that it reverses when encountering resistance.

- Tighten loose hardware – Check all brackets, hinges, rollers, and fasteners. Tighten any loose nuts, bolts or screws to prevent damage from vibrations.

- Replace weatherstripping – Over time, seals around the door perimeter and between sections can wear out. Replace worn weatherstripping to protect against drafts and leaks.

- Test opener safety features – Ensure automatic reverse, photo eyes, and other safety mechanisms are functioning properly on a regular basis. Make any necessary adjustments.

- Balance door – Springs can lose some tension over the years. Have a professional garage door technician balance the door every couple of years so it opens and closes properly.

Shopping for a New Garage Door

If it’s time to replace your garage door, think about these factors as you shop for a new one:

- Door material – Consider your budget, privacy needs, noise concerns, and aesthetic preferences when deciding between steel, wood, aluminum, vinyl, or fiberglass.

- Insulation rating – Check the R-value to choose a door with sufficient insulation for your climate zone. Higher R-values mean better insulation and energy efficiency.

- Size – Measure the width and height of your garage opening carefully to get a door with the proper dimensions for smooth operation.

- Spring type – Torsion springs are lower maintenance than extension springs. But extension springs take up less headroom.

- Automatic opener – Factor in adding a new opener system that meets current safety standards and has handy features like WiFi control.

- Warranty – Look for doors and openers that come with at least a 1-year warranty on parts and craftsmanship. Longer is better for such an important investment.

- Wind resistance – If you live in a high wind area, look for a sturdy door rated to withstand gusts up to your highest local wind speeds.

By understanding how the components work together to open and close your door, you can make better maintenance and replacement decisions down the road. Talk with a professional garage door contractor if you have any concerns about the condition or safety of your existing door. With proper care and quality parts, a new garage door should serve your home well for decades.

In Summary

Garage doors rely on a system of tracks, rollers, springs, cables, and electric openers to smoothly transition from vertical to horizontal and back again countless times throughout their lifespan. With quality materials and proper maintenance, your garage door will function safely and securely for many years to come, keeping your home and belongings protected.

Frequently Asked Questions

What is the average cost to replace a garage door?

The average cost to replace a standard two-car garage door ranges from $800-$1,500 including professional installation. Luxury wood doors or those with special insulation can cost $2,000-$4,000.

How much does it cost to install an automatic garage door opener?

Adding an automatic opener to an existing manual door costs $125-$300 for a basic chain-drive model or up to $400-$750 for a quiet belt-drive opener with more features.

How long do garage door torsion springs last?

On average, residential torsion springs last 10,000-15,000 open/close cycles. With daily use, they typically need replacement after 5-7 years. Signs it’s time are increased vibration or doors that no longer open smoothly.

How do I lubricate my garage door?

Use silicone spray lubricant on all rollers and hinges. Avoid grease, which attracts dirt. Applying lubricant twice per year keeps the door moving quietly and reduces strain on parts.

How do I balance my garage door?

Only a trained professional should adjust torsion springs for proper balance. But for doors with extension springs, you can adjust cable length by loosening cable clamps and resetting them in a different notch to raise or lower that side.